Having a product does not mean it’s going to work well. Having a product and having the experience to use it properly, that’s the determining factor. – Trace Blackmore

Having a product does not mean it’s going to work well. Having a product and having the experience to use it properly, that’s the determining factor. – Trace Blackmore

Dive into one of Trace Blackmore’s favorite formats: the “Pinks and Blues” episode! In this special installment, Trace tackles real-world questions from water treatment professionals like you, offering clear, practical solutions rooted in chemistry, strategy, and years of experience. From mastering serial dilutions to making the most of leftover competitor products, this episode is all about equipping you with the tools to excel in your field.

Managing Leftover Competitor Products in Accounts

Trace discusses the common challenge of customers asking water treatment professionals to use leftover chemicals they’ve already paid for. He highlights the risks of taking these products back to your facility, including potential costly disposal fees, and provides practical advice on how to manage and utilize these products effectively on-site.

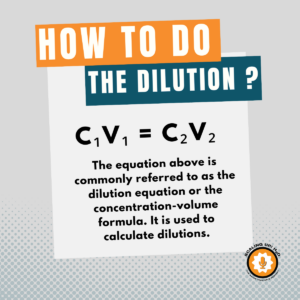

Serial Dilution: Explanation and Equation

Trace introduces the dilution formula C1 × V1 = C2 × V2, a fundamental equation for performing accurate dilutions. He provides a detailed, step-by-step guide to creating dilutions in both lab and field settings, enabling water treatment professionals to test and effectively utilize mystery products left behind by competitors.

Importance of Deionized (DI) Water in Test Kits

Trace explains the critical role of DI water in performing accurate dilutions and removing interferences during tests. He emphasizes the necessity of always carrying sufficient DI water in the field for tasks like dilutions, triple rinsing equipment, and managing high-concentration samples. Ensuring DI water availability is key to maintaining clean and reliable testing processes.

Testing Mystery Products

Trace recommends testing mystery products for key components such as phosphate (total, organic, and inorganic) and Azol levels to determine their composition. Use the product’s safety data sheet (SDS) or similar documentation to identify expected ranges and compare test results. These insights help calculate appropriate dosages and ensure effective usage of leftover products.

Benefits of Proper Product Management

Using leftover chemicals on-site provides several key advantages:

- Cost Savings: Eliminates expensive disposal fees for unused products.

- Customer Satisfaction: Reduces customer expenses by utilizing materials they’ve already paid for.

- Sustainability: Promotes greener practices by minimizing waste and maximizing resource efficiency.

- Professional Growth: Savings from proper management can support funding for training, certifications, and industry conferences, contributing to career development opportunities.

Be Part of the Discussion

We want to hear from you! Your contributions help shape the Scaling Up H2O podcast and make it even more valuable for the community.

- Submit Questions & Feedback: Your input drives our content. Send us your questions to be featured in future episodes.

- Share Your Success Stories: Let us know how this episode has helped you improve your water treatment practice or solve a challenging problem.

Stay engaged, keep learning, and continue scaling up your knowledge!

Timestamps:

07: 25 – Upcoming Events for Water Treatment Professionals

12:24 – Trace answers listener questions about managing leftover competitor products in water treatment accounts

15:32 – Trace explains Serial Dilution: Step-by-Step Guide

45:23 – Drop by Drop with James McDonald

Connect with Scaling UP! H2O

Submit a show idea: Submit a Show Idea

LinkedIn: in/traceblackmore/

https://www.linkedin.com/company/scalinguph2o/

YouTube: @ScalingUpH2O

Scaling UP! H2O Resources Mentioned

Audible (free month with this link)

AWT (Association of Water Technologies)

Scaling UP! H2O Academy video courses

Drop by Drop with James

In today’s episode, I have a challenge for you. The challenge is…check your safety equipment. Seriously, check the condition as well as any expiration dates. I personally was shocked to find out that hard hats have an expiration date on them, but they do. It does make sense, though, because plastic can get brittle over time, especially sitting in a hot vehicle. Brittle plastic probably won’t protect your noggin as well as it should. Are your safety glasses all scratched up or dirty? Do they obstruct your view? Do you wear your earplugs more than once, and do they need to be replaced? How about your steel-toed shoes, face shields, aprons, gloves, and other safety equipment? Will they protect you when you need them to? Take this challenge as your excuse to inspect them all and replace them as needed. Your family, friends, colleagues, Trace, and I all want you to be safe as you practice the noble profession of industrial water treatment!

Events for Water Professionals

Check out our Scaling UP! H2O Events Calendar where we’ve listed every event Water Treaters should be aware of by clicking HERE.